Transmission Tower

MOQ : 10 Units

Transmission Tower Specification

- Product Type

- Transmission Tower

- Material

- Mild Steel (MS)/Galvanized Iron (GI)

- Welding Standard

- AWS D1.1

- Capacity

- Customized as per requirement

- Application

- Power Transmission Lines

- Galvanization Standard

- IS 2629/ISO 1461

- Out Coating

- Hot Dip Galvanized

- Standard

- IS 2062/ASTM A36

- Shape

- Angular/Lattice

- Surface Treatment

- Galvanized

- Height

- Up to 100 meters

- Voltage

- 11 kV to 800 kV

- Design

- Modular/Lattice Design

- Thickness

- 3 mm to 20 mm

- Color

- Silver/Grey

- Maintenance

- Minimal

- Assembly

- On-site assembly

- Fabrication Technique

- Precision CNC & Plasma Cut

- Export Markets

- Worldwide

- Packaging

- Bundled and wrapped

- Corrosion Resistance

- High due to galvanizing

- Compliance

- International grid code compliant

- Quality Certifications

- ISO 9001:2015

- Operating Temperature Range

- -30°C to +55°C

- Foundation Type

- Concrete/Grouted

- Connection Type

- Bolted/Prefabricated

- Wind Load Resistance

- As per IS 802 standards

Transmission Tower Trade Information

- Minimum Order Quantity

- 10 Units

- Supply Ability

- 1000 Units Per Day

- Delivery Time

- 3 Week

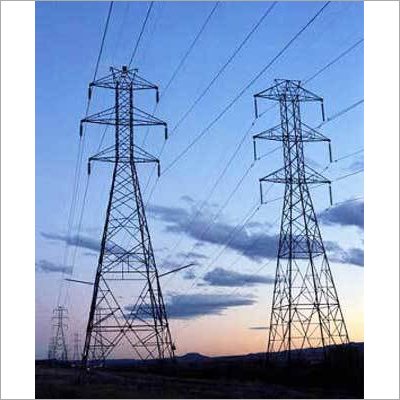

About Transmission Tower

In order to meet the varied requirements of our clients we are engaged in providing Transmission Tower that is known for its corrosion resistant surface, rugged construction and easy to install. Demanded by telecom companies for transmitting telecom signals, the entire range is used to supply electricity. In addition to this, Transmission Tower is best suited for installation of communication equipment for easy receiving and transferring of signals. These are purchased by the clients at highly affordable prices.

Engineered for Extreme Conditions

Transmission Towers are built to withstand operating temperature ranges from -30C to +55C and high wind loads, ensuring reliable performance across diverse geographical locations. The hot-dip galvanized surface offers outstanding corrosion resistance, making these towers ideal for harsh environments.

Precision Fabrication and Quality Assurance

Employing advanced CNC and plasma cutting techniques, every tower component meets stringent dimensional accuracy. With welding to AWS D1.1 standards and adherence to IS 2062/ASTM A36 for material quality, these towers deliver strength and durability, reinforced by ISO 9001:2015 certification.

FAQs of Transmission Tower:

Q: How are these transmission towers assembled at the site?

A: The transmission towers are designed for on-site assembly, featuring bolted or prefabricated connections. This allows for efficient construction and straightforward installation, even in remote areas.Q: What wind load resistance do the towers offer according to IS 802 standards?

A: These towers adhere to IS 802 standards for wind load resistance, enabling safe operation even in areas subject to high wind speeds by ensuring structural stability.Q: When is maintenance required for these transmission towers?

A: Due to high corrosion resistance and robust surface treatment, maintenance requirements are minimal. Periodic inspection for structural integrity and connection tightness is recommended as good practice.Q: Where can these towers be exported and used?

A: The towers are supplied worldwide by distributors, exporters, manufacturers, and traders, and can be installed wherever international grid code compliance is necessary, including various voltage levels and climates.Q: What benefits does the hot-dip galvanized coating provide?

A: Hot-dip galvanizing as per IS 2629/ISO 1461 standards delivers high corrosion resistance, significantly extending service life and reducing maintenance frequency, particularly in humid or coastal environments.Q: How is the quality of these towers ensured during manufacturing?

A: Quality assurance is maintained through ISO 9001:2015 certification, precision CNC and plasma cutting fabrication, and compliance with relevant material and welding standards, guaranteeing consistent and reliable product output.Q: What applications are suitable for this tower design?

A: These towers are tailored for power transmission lines and offer modular or lattice configurations, making them ideal for accommodating variable voltages from 11 kV to 800 kV in regional and international grids.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Transmission Tower Category

Power Transmission Tower

Price 3000.00 INR / Unit

Minimum Order Quantity : 10 Units

Product Type : Power Transmission Tower

Voltage : 110 kV 765 kV

Welding Standard : IS 9595 / AWS D1.1

Galvanization Standard : ASTM A123 / IS 2629 (Hot Dip Galvanized)

Electrical Transmission Tower

Price 3000.00 INR / Unit

Minimum Order Quantity : 10 Units

Product Type : Transmission Tower

Voltage : 11 kV to 765 kV

Welding Standard : AWS D1.1

Galvanization Standard : ASTM A123

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS