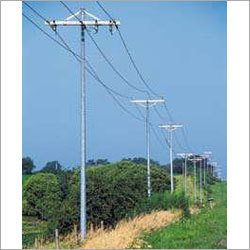

Industrial Electrical Transmission Pole

Price 3000.00 INR/ Unit

Industrial Electrical Transmission Pole Specification

- Product Type

- Electrical Transmission Pole

- Material

- Mild Steel/Steel

- Welding Standard

- IS 9595/IS 10178

- Capacity

- Upto 5000 kg

- Application

- Electrical Power Transmission

- Galvanization Standard

- IS 2629/BSEN ISO 1461

- Out Coating

- Hot Dip Galvanized

- Standard

- IS 2713/BS4360/ASTM A123

- Shape

- Octagonal/Polygonal/Tubular

- Surface Treatment

- Galvanized

- Height

- 6 Meter to 30 Meter

- Voltage

- 33KV - 400KV

- Design

- Custom/Standard

- Thickness

- 3 mm - 10 mm

- Color

- Silver

- Connection Type

- Flange/Slip Joint

- Wind Resistance

- 160 km/h to 200 km/h

- Corrosion Resistance

- Yes

- Base Plate

- Yes, with Anchor Bolts

- Production Technique

- Automatic Welding

- Maintenance

- Low

- Finish

- Smooth/Uniform

- Mounting Type

- Ground Mounted

Industrial Electrical Transmission Pole Trade Information

- Minimum Order Quantity

- 10 Units

- Supply Ability

- 1000 Units Per Day

- Delivery Time

- 3 Week

About Industrial Electrical Transmission Pole

Our Industrial Electrical Transmission Pole is a dependable and durable option for sending electrical power across great distances. They are built to withstand severe weather and environmental variables. In order to provide the effective and safe transmission of power over great distances, they have been built to support enormous loads of electrical cables. Industrial Electrical Transmission Poles work well over a long period, require little maintenance, and are simple to install. Power plants, sub-stations, and other heavy-duty electrical transmission installations are merely a few of the industrial uses that they are suitable for.

Superior Structural Integrity and Safety

Designed to endure harsh conditions, these transmission poles offer exceptional wind and corrosion resistance, safeguarding electrical infrastructure in demanding environments. Automatic welding and standardized galvanization processes ensure lasting durability and low maintenance, making them ideal for reliable operation in industrial and utility settings.

Versatile Design and Customization

Available in a range of shapes, heights, and thicknesses, the poles can be tailored to meet various project specifications. With options for flange or slip joint connections and capacities up to 5000 kg, customers can choose both standard and custom solutions for power transmission applications across India and global markets.

Effortless Installation and Minimal Maintenance

Ground-mounted with base plates and secure anchor bolts, our transmission poles are engineered for quick setup and long service life. Their smooth, hot-dip galvanized finish and advanced welding techniques minimize routine upkeep, reducing overall lifecycle costs and ensuring consistent performance.

FAQs of Industrial Electrical Transmission Pole:

Q: How are these industrial electrical transmission poles installed?

A: These poles are ground-mounted using a base plate and anchor bolts, ensuring a stable foundation. The installation process leverages flange or slip joint connections, allowing for efficient assembly onsite and compatibility with various project layouts.Q: What makes these transmission poles suitable for high-wind areas?

A: Engineered to withstand wind speeds from 160 km/h to 200 km/h, the poles feature robust steel construction, automatic welding, and precise galvanization. This combination ensures structural reliability even under extreme weather conditions.Q: When should I consider using a custom-designed transmission pole?

A: Custom designs are ideal when standard sizes, shapes, or load capacities do not meet specific project needs. Our manufacturing supports tailored dimensions, thickness, and voltage compatibility depending on your transmission requirements.Q: Where are these transmission poles primarily used?

A: They are widely deployed in electrical power transmission networks, especially for distributing voltages from 33KV up to 400KV. Common applications include urban, rural, and industrial grid infrastructure across India and suitable export markets.Q: What is the production process and surface treatment for these poles?

A: Production involves automatic welding for consistent joint strength, followed by hot-dip galvanization meeting IS 2629/BSEN ISO 1461 standards. This smooth, uniform coating ensures excellent corrosion resistance for prolonged service life.Q: How does the hot-dip galvanization benefit the poles longevity?

A: Hot-dip galvanization forms a protective zinc layer over the steel, significantly enhancing resistance to corrosion from moisture, chemicals, and outdoor exposure, translating into longer service intervals and reduced maintenance.Q: What are the main benefits of choosing these ground-mounted transmission poles?

A: Key advantages include robust wind and corrosion resistance, high capacity (up to 5000 kg), low maintenance demands, and versatile applications. These features ensure reliable power transmission and cost-effective performance over an extended lifespan.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mono Pole Category

Distribution Mono Pole

Price Range 300000.00 - 400000.00 INR / Unit

Minimum Order Quantity : 10 Units

Product Type : Distribution Mono Pole

Shape : Round/Conical/Polygonal

Surface Treatment : Galvanized

Material : Mild Steel

Steel Lighting Pole

Price Range - 400000.00 INR / Unit

Minimum Order Quantity : 10 Units

Product Type : Lighting Pole

Shape : Octagonal

Surface Treatment : Galvanized

Material : Mild Steel

Decorative pole

Minimum Order Quantity : 10 Units

Product Type : Decorative Lighting Pole

Shape : Round / Tubular

Surface Treatment : Galvanized and Powder Coated

Material : Mild Steel (MS)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS