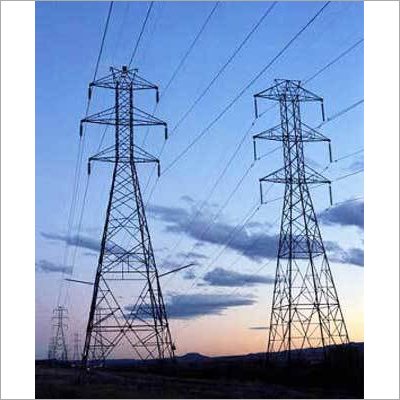

Power Transmission Tower

Price 3000.00 INR/ Unit

Power Transmission Tower Specification

- Product Type

- Power Transmission Tower

- Material

- Mild Steel / High Tensile Steel

- Welding Standard

- IS 9595 / AWS D1.1

- Capacity

- Up to 1000 kN loading

- Application

- Transmission and Distribution of Electricity

- Galvanization Standard

- ASTM A123 / IS 2629 (Hot Dip Galvanized)

- Out Coating

- Zinc Coated

- Standard

- IS 2062 / ASCE / IEC Standards

- Shape

- Lattice Steel Structure

- Surface Treatment

- Hot Dip Galvanizing

- Height

- Up to 65 meters (customizable)

- Voltage

- 110 kV 765 kV

- Design

- Modular, Customizable Design

- Thickness

- 3 mm 30 mm (customized)

- Color

- Metallic Silver

- Foundation Type

- Cast-in-situ concrete footings

- Accessories

- Insulator Brackets, Cross Arms, Ladders, Platforms, Bird Guards

- Inspection

- Ultrasonic & Radiographic Weld Testing

- Corrosion Resistance

- High, suitable for outdoor installations

- Fabrication Method

- Automated CNC cutting and drilling

- Installation Type

- On-site assembly

- Packing

- Standard export seaworthy packing

- Bolt Type

- Hot Dip Galvanized High Tensile Bolts & Nuts

- Wind Load Resistance

- Designed for region-specific wind loads

- Maintenance

- Low maintenance due to superior galvanization

- Compliance

- Meets PGCIL / TANGEDCO / SEB Specifications

Power Transmission Tower Trade Information

- Minimum Order Quantity

- 10 Units

- Supply Ability

- 1000 Units Per Day

- Delivery Time

- 3 Week

About Power Transmission Tower

There are several types of power transmission towers, including lattice towers, guyed towers, and monopole towers. Lattice towers are the most common type and are characterized by their triangular lattice structure. Guyed towers use guy wires to provide additional support, while monopole towers are single-pole structures that require less land space but are typically more expensive to construct.Power transmission towers are critical infrastructure components for the electrical power grid and play an essential role in delivering reliable and efficient electricity to homes, businesses, and industries. They are subject to strict design and construction standards to ensure their safety, reliability, and longevity.

We would like to introduce our Power Transmission Tower as the perfect means of sending electricity over large distances. To ensure sturdiness, strength, and long-lasting performance, our towers are designed and made utilising premium materials. Our Power Transmission Towers are built from durable steel and are designed to withstand the worst weather and environmental conditions. Electricity is transmitted safely and effectively over long distances because to the towers' ability to support enormous weights of electrical wires.

Superior Corrosion Resistance

Our towers feature hot dip galvanizing to ASTM A123 and IS 2629 standards, providing high corrosion resistance even in harsh outdoor conditions. The zinc-coated finish ensures longevity and reduces maintenance costs, preserving structural integrity over time.

Region-Specific Wind Load Design

Each transmission tower is engineered to withstand local wind loads, guaranteeing reliable performance under various environmental pressures. The modular, customizable design enables adaptation to site-specific requirements, ensuring operational stability and safety.

Automated Precision Fabrication

Utilizing automated CNC cutting and drilling, every component is manufactured to exact specifications. Ultrasonic and radiographic weld testing further enhance safety, while compliance with IS 9595, AWS D1.1 welding standards, and IS 2062/ASCE/IEC material standards assures unmatched quality.

FAQs of Power Transmission Tower:

Q: How is the corrosion resistance of the transmission tower ensured?

A: The transmission tower surface undergoes hot dip galvanizing to ASTM A123 and IS 2629 standards, resulting in a zinc coated layer that protects against corrosion. This treatment makes the tower suitable for long-term outdoor exposure and reduces maintenance frequency.Q: What is the installation process for these towers?

A: Installation involves on-site assembly of lattice steel components using high tensile, hot dip galvanized bolts and nuts. The foundation is constructed with cast-in-situ concrete footings, followed by the mounting of accessories such as insulator brackets, cross arms, ladders, platforms, and bird guards.Q: When are ultrasonic and radiographic weld inspections conducted?

A: Ultrasonic and radiographic weld inspections are performed during and after the automated CNC fabrication process to confirm weld integrity, ensuring safety and compliance with IS 9595 and AWS D1.1 standards before installation.Q: Where can these towers be used?

A: Designed for transmission and distribution of electricity, these towers are suitable for use in a wide range of outdoor locations, adapted for region-specific wind loads. They are widely used by utilities including PGCIL, TANGEDCO, and SEBs throughout India.Q: What are the benefits of modular and customizable tower design?

A: The modular structure allows for efficient transportation and flexible assembly on-site. Customizable height (up to 65 meters) and load capacity (up to 1000 kN) enable tailored solutions to meet project-specific transmission requirements.Q: How frequently does the tower require maintenance?

A: Thanks to superior galvanization and durable materials, the tower demands minimal maintenance. Routine visual inspections and standard cleaning may be performed, but no frequent corrosion treatment is necessary.Q: Which accessories are provided with the transmission tower?

A: Standard accessories include insulator brackets, cross arms, ladders, working platforms, and bird guards, facilitating safe operation and maintenance, while accommodating transmission hardware for various voltage levels.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Transmission Tower Category

Electrical Transmission Tower

Price 3000.00 INR / Unit

Minimum Order Quantity : 10 Units

Height : Up to 100 meters

Application : Electrical Power Transmission

Standard : IS 802, IS 2062, BS EN ISO 1461

Transmission Tower

Price Range 3000.00 - 400000.00 INR / Unit

Minimum Order Quantity : 10 Units

Height : Up to 100 meters

Application : Power Transmission Lines

Standard : IS 2062/ASTM A36

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free