Electrical Transmission Tower

Price 3000.00 INR/ Unit

MOQ : 10 Units

Electrical Transmission Tower Specification

- Product Type

- Transmission Tower

- Material

- High Tensile Steel

- Welding Standard

- AWS D1.1

- Capacity

- Supports multi-circuit configurations

- Application

- Electrical Power Transmission

- Galvanization Standard

- ASTM A123

- Out Coating

- Hot Dip Galvanized

- Standard

- IS 802, IS 2062, BS EN ISO 1461

- Shape

- Lattice Type

- Surface Treatment

- Anti-Corrosion

- Height

- Up to 100 meters

- Voltage

- 11 kV to 765 kV

- Design

- Customized as per client specifications

- Thickness

- 3.0 mm to 18 mm

- Color

- Metallic Silver

Electrical Transmission Tower Trade Information

- Minimum Order Quantity

- 10 Units

- Supply Ability

- 1000 Units Per Day

- Delivery Time

- 3 Week

About Electrical Transmission Tower

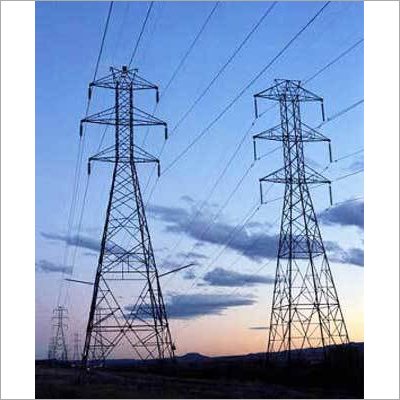

Electrical Transmission Tower

An electrical transmission tower, also known as an electricity pylon or power tower, is a tall structure used to support electrical power lines. These towers are typically made of steel or concrete and are designed to withstand the weight of the power lines and the forces exerted on them by the wind.Electrical transmission towers are used to transmit high-voltage electricity over long distances from power plants to substations or from one substation to another. The power lines are usually made of aluminum or copper and are strung between the towers using insulators to prevent electrical current from flowing through the tower.

Exceptional Structural Strength

Built using high-strength, hot-dip galvanized steel and advanced modular assembly, these transmission towers ensure durability and stability in diverse climates. With a thickness ranging from 3.0 mm to 18 mm and compliance with IS 802, IS 2062, and BS EN ISO 1461, the towers maintain structural integrity under heavy wind and seismic loads.

Flexible Installation and Maintenance

Choose between cast-in-situ or prefabricated foundations, adapting to various site conditions. The modular construction and bundle packing facilitate efficient transportation and convenient manual or mechanical assembly, while integrated ladders and low-maintenance features further simplify routine upkeep.

Customized Solutions for Power Transmission

Designed to support voltages from 11 kV to 765 kV and multi-circuit arrangements, every tower is tailored to specific client requirements. Suitable for diverse applications, from rural to urban power transmission networks, these towers offer reliable operation, safety, and longevity, maximizing investment value.

FAQs of Electrical Transmission Tower:

Q: How are the electrical transmission towers installed on site?

A: The towers can be assembled manually or with mechanical assistance using modular components. They support either cast-in-situ or prefabricated foundations, enabling flexible installation to suit various terrain and site conditions.Q: What makes the transmission towers resistant to harsh environments?

A: With hot-dip galvanization (ASTM A123), anti-corrosion surface treatments, and robust lattice construction using high-tensile steel, the towers are engineered to withstand temperatures from -30C to +55C, wind speeds up to 180 km/h, and seismic loads up to Zone V.Q: When is maintenance required for these towers, and how demanding is it?

A: Maintenance intervals are minimal due to the towers durable, corrosion-resistant coatings and strong construction. Occasional inspections are recommended, but regular upkeep is low compared to traditional structures, ensuring over 35 years of reliable service.Q: Where can these towers be used?

A: Designed for electrical power transmission and distribution, these towers are suitable for installation in rural, urban, coastal, or seismic-prone regions across India and internationally, thanks to their versatile foundational and environmental adaptability.Q: What accessories and features are included with the tower?

A: Each tower includes an integrated ladder for climbing, earthling provisions, insulators, cross arm, bracing, and optional anti-theft locking mechanisms. Bundle packing with markings ensures ease of transport and on-site identification.Q: How does the tower benefit power transmission operations?

A: The towers provide reliable, long-term support for multiple circuits, enhanced safety through stable design, and low maintenance requirements. Customization options allow adaptation to specific voltage, height, and client needs, ensuring efficiency and cost-effectiveness.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Transmission Tower Category

Power Transmission Tower

Price 3000.00 INR / Unit

Minimum Order Quantity : 10 Units

Welding Standard : IS 9595 / AWS D1.1

Surface Treatment : Hot Dip Galvanizing

Standard : IS 2062 / ASCE / IEC Standards

Transmission Tower

Price Range 3000.00 - 400000.00 INR / Unit

Minimum Order Quantity : 10 Units

Welding Standard : AWS D1.1

Surface Treatment : Galvanized

Standard : IS 2062/ASTM A36

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free